-

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy!

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy! -

Carolina FasioOn-time delivery. And support is good and fast.

Carolina FasioOn-time delivery. And support is good and fast.

2J4 Iron Cobalt Hysteresis Permanent Magnet Alloy Corrosion Resistance

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Equal Grade | 2J4 | Spec | GB/T 14988-1994 |

|---|---|---|---|

| Thickness | 0.05-1.0mm | Density | 8.2g/cm3 |

| Chemical Composition | Cobalt-Nickel-Vanadium | Type | Hysteresis Alloy |

| Highlight | 2J4 Permanent Magnet Alloy,Permanent Magnet Alloy Anti Corrosion,Hysteresis Permanent Magnet Alloy |

||

2J4 Iron-Cobalt Hysteresis Permanent Magnet Alloy Corrosion resistance

2J4 is a Iron-Cobalt-Nickel-Vanadium hysteresis alloy which combines the advantage of high hysteresis loss and low magnetizing force.

It exhibits the highest efficiency(loss per unit magnetizing force) of any known material. That is why it is widely used in hysteresis motor applications.

2J4 belongs to Iron-Cobalt Permenent Magnetic Alloy,this alloy is suitable for making high efficiency hysteresis motor rotor with high operating temperature, and this alloy does not cause reduced magnetic performance in the range of + 150~ -140 ℃. In all kinds of the Magnetic Alloys, 2J4 is the one with a long application time and a large dosage. We can supply cold rolled strip of 2J4 alloy with mature process and stable quality in thickness range 0.05-1.0mm.

.Density of 2J4: 8.2g/cm 3

Machenical properties

Good plasticity before tempering

General Welding performance

Good magnetic stability

Corrosion resistance properties

Good forming performance after continuous rolling

Standards

GB/T 14988-1994

The available forms

Cold rolled strip in thickness range 0.05-1.0mm.

Other thickness also availble per request.

Chemical composition

| C | ≤0.12 |

| P | ≤0.025 |

| S | ≤0.02 |

| Si | ≤0.70 |

| Mn | ≤0.70 |

| Co | 44.0~46.0 |

| V | 3.5~4.5 |

| Ni | 5.30~6.70 |

| Fe | Balance |

Advantages

High hysteresis loss

Low magnetizing force

Highest efficiency (loss per unit magnetizing force) of any known material

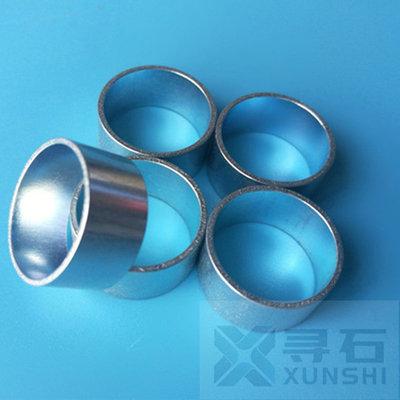

Application

Magnetic motor rotor, Magnetic brake

![]()

![]()

![]()

About XUNSHI

Suzhou Xunshi New Material Co. Ltd- referred as XUNSHI hereafter, is a professional manufacturer of high-performance alloy products. XUNSHI is engaged in supplying high quality and cost-effective Superalloy, Anti-Corrosion Alloy, Precision Alloy, Special Stainless Steel and Magnetostrictive Material to customers worldwide.

Why XUNSHI

· Highly experienced in alloy industry

· Top experts of industry in China

· Advanced technology and process from top famous institutes in China

· Advanced devices through whole production and inspection process

· Strict quality control system

· Company motto: best service, most value

· Smart sales policy

Service Items of XUNSHI

· Non-standard product research and pre-production

· Fabrication of products

· Cutting, splitting for sheets and plates in stock

· Heat treatment (Solution treatment, aging harden treatment, anneal, spring temper, quench etc.)

· Surface finish (peeling, gridding, polishing)

· Logistics service

· Customized packing service (also for exporting)

· Import and export (XUNSHI is certificated)

· Document translation

· Hard-to-find material sourcing

Customers of XUNSHI

Customers of XUNSHI are all over China (Taiwan and Hong Kong included). And we are exporting to USA, Canada, Italy, UK, Poland, Greece, Russia, Turkey, Iran, Israel, South Africa, South Korea, North Korea, India, Argentina, and Brazil and so on. Customers from 30+ countries trust us.

Where is XUNSHI

A- XUNSHI is in Huaqiao, Kunshan, 215332 China, which is very closed to Shanghai.

B- Xunshi is around 80KM from Shanghai Pudong International Airport (PVG).

C- 20KM from Shanghai Hongqiao Airport

D- 20KM from Shanghai Hongqiao Railway Station

E- You can contact XUNSHI sales for a pickup service.