-

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy!

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy! -

Carolina FasioOn-time delivery. And support is good and fast.

Carolina FasioOn-time delivery. And support is good and fast.

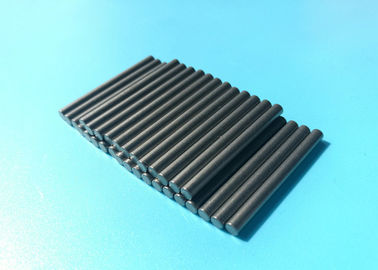

2J83, 2J84, 2J85 Wrought Iron-Chromium-Cobalt Permenent Magnet Alloys

| Spec | YB/T 5261-2016 | Type Of Alloy | FeCrCo |

|---|---|---|---|

| Density | 7.7g/cm3 | Melting Range | 1530~1600°C |

| Tc | 671°C | Resistivity | 0.64~0.80 μΩ·m |

| Highlight | precipitation hardening alloys,cobalt iron alloy |

||

2J83, 2J84, 2J85 Wrought Iron-Chromium-Cobalt Permenent Magnet Alloys

Iron-chromium-cobalt permanent magnet alloy not only has good ductility, but also has good magnetic properties. It is the most widely used deformable permanent magnet material at present. Its magnetic properties are comparable to cast aluminum nickel cobalt alloy, and the price is cheaper than iron cobalt vanadium permanent magnet alloy. The alloy is characterized by homogeneous composition, compact structure and stable performance. It can replace some cast Al-Ni-Co alloys and Fe-Co-V alloys to make complex permanent magnet components.

Chemical composition

| C | Mn | S | P | Cr | Co | Si | Mo | Ti | Fe | |

| 2J83 | 0.030 max | 0.20 max | 0.030 max | 0.020 max | 26.0~27.5 | 19.5~21.0 | 0.80~1.10 | - | - | Rem |

| 2J84 | 0.030 max | 0.20 max | 0.030 max | 0.020 max | 25.5~27.0 | 14.5~16.0 | - | 3.00~3.50 | 0.50~0.80 | Rem |

| 2J85 | 0.030 max | 0.20 max | 0.030 max | 0.020 max | 23.5~25.0 | 11.5~13.0 | 0.80~1.10 | - | - | Rem |

Characters

- Heat resistant: magnetism does not decline below 400 degrees

- Can be machined, such as cutting, tapping, drilling, stamping, etc.

- Impact resistance while other magnetic materials are fragile and easy to crack.

- Magnetic requirements can be adjusted according to customer needs (semi hard magnetic properties can be made).

- Good corrosion resistance

Magnetic properties

| Grade | Type | Br/T | Hc(kA/m) | (B·H)max/(kJ/m3) |

| 2J83 | anisotropy | 1.05 min | 48 min | 24~32 |

| 2J84 | anisotropy | 1.20 min | 52 min | 32~40 |

| 2J85 | anisotropy | 1.30 min | 44 min | 40~48 |

Applications

This alloy is mainly used in all kinds of aviation, ships, automotive instruments, magnetic compass diameter, oil logging tools, level indicators, signal generators, burglars, counters, embroidery machines, hearing aids, etc.

Forms of supply

- Hot forged bars

- Hot rolled flat bars

- Cold drawn wire

- Cold rolled strip