-

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy!

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy! -

Carolina FasioOn-time delivery. And support is good and fast.

Carolina FasioOn-time delivery. And support is good and fast.

580~640 °C Vanadium Cobalt Iron Alloy 2J31 For Cold Rolled Strip Cold Drawn Wire

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Spec | GB/T 14989-2015 | Thickness | 0.20~1.00mm |

|---|---|---|---|

| Forms Of Supply | Cold Rolled Strip, Cold Drawn Wire | Hc | 17.51 KA/m |

| Br | 1.00 T | Br·Hc | 19.10 KJ/m3 |

| Highlight | precipitation hardening alloys,magnetic materials,Vanadium Cobalt Iron Permanent Magnet Alloy |

||

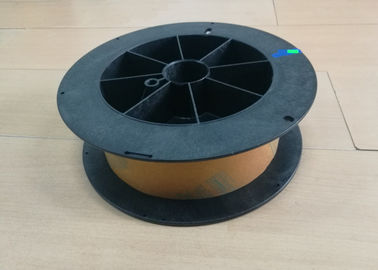

2J31 Iron-Cobalt-Vanadium Permanent-Magnet Alloy Cold Rolled Strip

A-ONE ALLOY is able to produce 2J31 permenent magnet alloy in forms of wire, strip or per customer requirement.

2J31 is used to make small section permanent magnet and recording material.

Forms available: cold drawn wire and cold rolled strip

Size range:

Wire diameter: 0.05~3.0mm

Strip thickness: 0.20~1.00mm

Chemical composition

| Element | C | Si | Mn | P | S | Ni | Co | V | Fe |

| Weight(%) | 0.12 max. | 0.50 max. | 0.50 max. | 0.025 max. | 0.020 max | 0.70 max. | 51.0~53.0 | 10.8~11.7 | Balance |

Delivery condition: without heat treatment

The parts should be heat treated after they are processed to get required magnetic properties.

Magnetic properties(after heat treatment)

| Form | Cold drawn wire | Cold rolled strip | ||||

| Parameter |

Hc (kA/m) |

Br (T) |

Br·Hc (kJ/m3) |

Hc (kA/m) |

Br (T) |

Br·Hc (kJ/m3) |

| Value | 23.88 min. | 1.00 min. | 23.88 min. | 17.51 min. | 1.0 min. | 19.10 min. |

Heat treatment

| Grade | Temperature(°C) | Duration(min) | Cooling |

| 2J31 | 580~640 | 20~60 | air cool |