-

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy!

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy! -

Carolina FasioOn-time delivery. And support is good and fast.

Carolina FasioOn-time delivery. And support is good and fast.

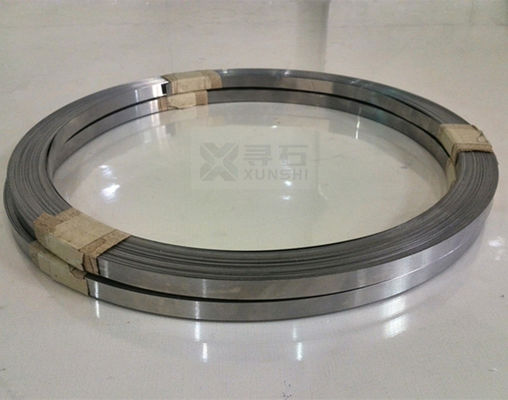

R30003 AMS 5876 D Super Elastic Material , Cobalt Corrosion Heat Resistant Alloys

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Grade | R30003 | Product Name | Super Elastic Material |

|---|---|---|---|

| Cobalt | 39-41% | Chromium | 19-21% |

| Resistance | Corrosion Heat Resistant | Certification | ISO9001:2015 |

| Equal Grade | Phynox, Elgiloy, R30003 | ||

| Highlight | shape memory alloys,shape memory materials |

||

R30003 AMS 5876 D Corrosion and Heat-Resistant Cobalt Alloy Cold Rolled Strip

R30003 is a "super-alloy" consisting of 39-41% Cobalt, 19-21% Chromium, 14-16% Nickel, 11.3-20.5% Iron, 6-8% Molybdenum, and 1.5-2.5% Manganese. In China it is called Co40CrNiMo, 3J21-3Jxx is a series of elastic alloys.

It is used to make springs that are corrosion resistant and exhibit high strength, ductility, and good fatigue life. These same properties led to it being used for control cables in the Lockheed SR-71 Blackbird airplane.

UNS R30003 meets specifications AMS 5876, AMS 5833.

Due to its chemical composition, R30003 is highly resistant to sulfide stress corrosion cracking and pitting, and can operate at temperatures up to 454°C.

Chemical composition

![]()

Typical Mechanical Property of R30003 Strip

|

Thickness mm |

Tensile Strength Rm/Mpa |

Yield Strength Rp0.2/MPa |

Elongation A,(%)≥ |

Hardness HV |

| T0.10 | 1398 | 1327 | 14.5 | 451 |

| T0.127 | 1523 | 1285 | 4.0 | 466 |

| T0.15 | 1555 | 1508 | 14.0 | 468 |

| T0.30 | 967 | 484 | 66 | 273 |

| T1.20 | 1611 | 1538 | 9.5 | 458 |

| T1.60 | 1612 | 1466 | 8.5 | 447 |

| T2.05 | 1556 | 1448 | 12.0 | 461 |

Specs

- AMS 5876

- AMS 5833

- ASTM F1058 Grade 1

- YBT 5253-2011 China

Key features

- Combination of high strength, ductility, and good mechanical properties at ambient temperatures

- Excellent fatigue life

- Excellent corrosion resistance in numerous environments

- Nonmagnetic

- Age hardenable (Spring Temper only)

- Good for sea water applications

Application

- Springs

- Seal components

- Medical devices

- Components for watches

- Aerospace applications

- Petro-chemical applications

- Marine engineering

Forms of supply

- Cold rolled strip

- Cold drawn wire

- Hot forged bar

- Hot rolled bar

XUNSHI is proud to be able to supply R30003 products that meet the requirement of AMS 5876 D and AMS 5833 and ISO 5832-7.

![]()

![]()

![]()

![]()

![]()

![]()

About XUNSHI

Suzhou Xunshi New Material Co. Ltd- referred as XUNSHI hereafter, is a professional manufacturer of high-performance alloy products. XUNSHI is engaged in supplying high quality and cost-effective Superalloy, Anti-Corrosion Alloy, Precision Alloy, Special Stainless Steel and Magnetostrictive Material to customers worldwide.

Why XUNSHI

· Highly experienced in alloy industry

· Top experts of industry in China

· Advanced technology and process from top famous institutes in China

· Advanced devices through whole production and inspection process

· Strict quality control system

· Company motto: best service, most value

· Smart sales policy

Service Items of XUNSHI

· Non-standard product research and pre-production

· Fabrication of products

· Cutting, splitting for sheets and plates in stock

· Heat treatment (Solution treatment, aging harden treatment, anneal, spring temper, quench etc.)

· Surface finish (peeling, gridding, polishing)

· Logistics service

· Customized packing service (also for exporting)

· Import and export (XUNSHI is certificated)

· Document translation

· Hard-to-find material sourcing

Customers of XUNSHI

Customers of XUNSHI are all over China (Taiwan and Hong Kong included). And we are exporting to USA, Canada, Italy, UK, Poland, Greece, Russia, Turkey, Iran, Israel, South Africa, South Korea, North Korea, India, Argentina, and Brazil and so on. Customers from 30+ countries trust us.

Where is XUNSHI

A- XUNSHI is in Huaqiao, Kunshan, 215332 China, which is very closed to Shanghai.

B- Xunshi is around 80KM from Shanghai Pudong International Airport (PVG).

C- 20KM from Shanghai Hongqiao Airport

D- 20KM from Shanghai Hongqiao Railway Station

E- You can contact XUNSHI sales for a pickup service.