-

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy!

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy! -

Carolina FasioOn-time delivery. And support is good and fast.

Carolina FasioOn-time delivery. And support is good and fast.

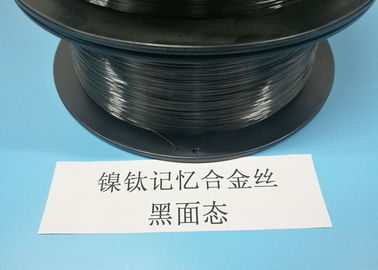

SMA Nitinol Wire Tube Shape Memory Alloys , 0.1-5.0mm Shape Memory Materials

| Form Of Supply | Wire, Tube | Density | 6.45g/cm3 |

|---|---|---|---|

| Diameter Range | 0.1-5.0mm | Melting Range | 1240~1310°C |

| Product Name | Shape Memory Alloys | Package | Carton, Plywood Case |

| Highlight | shape memory alloys,super elastic material |

||

Shape Memory Alloy SMA Nitinol with Shape Memory and Superelasticity

Nitinol combines two closely related unique characteristics: shape memory and superelasticity. Shape memory gives Nitinol the ability to be deformed at one temperature, and then return to its original shape when being heated to its transformation temperature. This effect is caused by the material changing from its low temperature monoclinic martensitic structure to the high temperature cubic austenitic structure. Transformation temperatures in our finished Nitinol wire range from -15°C to +22°C, depending on the grade of Nitinol used.

The VIM + VAR nitinol melting process was established in 1990 through extensive superalloy experience to provide premium, repeatable quality by combining the advantages of VIM (homogeneity) and VAR (structure). This mature process continues today, outputting several hundred thousand pounds of clean, consistent material every year.

Shape memory Nitinol wire can be used to develop implants that may be delivered into the body in a compact shape and then activated into their functional form once they have been deployed.

Appications

- Temperature control systems: as it changes shape, it can open or close a valve, activate a switch or a variable resistor to control the temperature.

- Demonstration model heat engines have been built which use SMA to produce mechanical energy from hot and cold heat sources.

- Aeronautical market: design of adaptive structures to control flaps or the chevron shape during taking off and landing phases.

- Actuators for automotive industry, such as latch mechanisms for doors and appendixes, air valves, adaptive structures, etc.

- Actuators for autofocus mechanisms in cameras.

- Triggering actuators for aerospace applications, especially in hold-down and release mechanisms in charge of deploying structures and appendixes in satellites.

- Healthcare: active implants, valves, catheters…

A-ONE ALLOY could make fast delivery for order quantity below 50kg within two weeks. We are always ready to provide the best experience for our customers from worldwide.