-

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy!

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy! -

Carolina FasioOn-time delivery. And support is good and fast.

Carolina FasioOn-time delivery. And support is good and fast.

FeCoVNi Permenent Magnetic P6 Alloy , Cold Rolled Strip Semi Hard Magnet Alloy

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

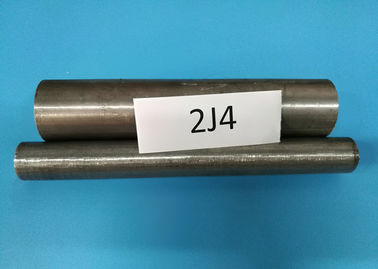

x| Certification | ISO 9001:2015 | Equal Grade | 2J4(China) |

|---|---|---|---|

| Form Of Supply | Cold Rolled Strip, Wire, Round Bar | Type | FeCoVNi |

| Thickness | 0.05-0.8mm | Product Name | Permanent Magnet Alloy |

| High Light | cobalt iron alloy,magnetic materials,Permanent Magnetic P6 Alloy |

||

P6 alloy is a cobalt base precipitation hardened alloy which combined the advantages of high hysteresis loss and low magnetizing force. It is similar to Vicalloy-2J10 in China standard.

Typical chemical composition P6 alloy

Ni: 6.0%

Co: 45.0%

V: 4.8%

Fe: Balance

Chemical composition 2J4 (%, weight)

C: 0.12 max

P: 0.025 max

S: 0.020 max

Si: 0.70 max

Mn: 0.70 max

Co: 44.0~46.0

V: 3.5~4.5

Ni: 5.3~6.7

Fe: Balance

Physical properties

Density: 8.2g/cm3

Curie point: 1580°F/860°C

Machenical properties

Hardness: HRC 40~46(before temper)

HRC 58~62 (after temper)

Tensile strength, σb: 882~1370MPa(before temper)

1180~1960Mpa(after temper)

Thickness range: 0.05~0.8mm

Other thickness also availble per request.

It is required to do a age hardening heat treatment after material fabricated to the desired form.

Placed in a protective atmosphere furnace and held at 550~600 degree for two to five hours.