-

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy!

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy! -

Carolina FasioOn-time delivery. And support is good and fast.

Carolina FasioOn-time delivery. And support is good and fast.

Hiperco 50A Soft Magnetic Alloy With High Magnetic Saturation 24 Kilogauss China Origin Fast Delivery

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Equal Grade | 1J21, Permendur 2V | Form Of Supply | Cold Rolled Strip, Hot Forged Round Bar |

|---|---|---|---|

| Spec | ASTM A801 Type 1 | Composition | Fe49Co49V2 |

| Highlight | 24 kilogauss Soft Magnetic Alloy,China Origin Soft Magnetic Alloy,High Soft Magnetic Alloy |

||

Hiperco0 50A alloy is an iron-cobalt-vanadium soft magnetic alloy possessing high magnetic saturation (24 kilogauss, 2.4T), high D.C

maximum permeability, low D.C. coercive force, and low A.C. core loss. This alloy exhibits magnetic properties superior to those of

other commercial iron-cobalt soft magnetic alloys.

In addlition. XUNSHI produces Hiperco 50 alloy which has nearly the same nominal analysis as Hiperco 50A alloy but contains

small additions of niobium and carbon for grain refinement to achieve higher mechanical strengths with only a slight sacrifice in

magnetic properties. Hiperco 50 alloy's higher strength is necessary for rotating component laminations subject to stress from high

rotational speeds. Hiperco 50 alloy has been used in strip form primarily for aircraft generators and motors.

Please contact XUNSHI for further technical data.

Typical composition

C=0.001%, Mn=0.05%, Si=0.05%, Co=48.75%, V=2.0%, Fe=balance

Applications

Hiperco 50A alloy has been used primarily for magnetic cores in electrical equipment requiring high permeability at high magnetic flux

densities. lt has also been used in tape cores where lowest A.C. losses and high permeability at high inductions are desired.

Heat Treatment

Anneal parts at 1575/1600F (8571871°C) for 2 to 4 hours in dry hydrogen or vacuum and cool at 150/350° (83/194'C) per hour until 600°F(316 °C) is reached, after which any cooling rate can be employed.

It is important to avoid any contamination of the finished fabricated parts during the heat treatment. All parts must be cleaned thoroughly to remove any surface contaminants prior to being placed in an air-tight retort.

A dry hydrogen atmosphere or a high vacuum is recommended to minimize oxide contamination of the parts during annealing. When hydrogen is employed, the entry dew point should be dryer than -60° (-51 C) and the exit dew point dryer than about -40%F (-40 °C) when the inside retort temperature is above 900°F (482C).

Optional Treatments

For Centerless Ground Bars less than 1.250" (31.75 mm) Diameter -

This duplex practice is only recommended for centerless ground bars in the size range given. Larger centertess ground bars, shapes

or hot rolled bars may be subject to cracking if auenched in this manner, This is a two-sten reatment where the first sten conditions

the material for best machinability while the second develops optimum magnetic properties.

Preheat treat 2 to 3 foot lenaths at 1850 (1010°C) for about 30 minutes in air or protective atmosphere and quench bars in cold acitated water with their long axes in the verfical position. This preheat treatment develops a coarse acicular martensitic type structure which imparts ductility to the material and improves machining of the finish part.

The second part of the duplex treatment involves the employment of the standard treatment as described earlier. At no time should the temperature of the second treatent exceed 1600° (871°C) because of the formation of a nonmagnetic austenitic phase which transforms upon cooling, thereby degrading magnetic properties due to transformation stresses.

For Products Produced from Any Size Bar

This practice can be applied to al parts produced from bar prducts. regardless of their size since no rapid quench practices are

required.lt provides improved capability magnetic properties on especially large cross sections compared to those of the standard

heat treatment. Note, however, it is a lengthy process and, therefore, more expensive

Heat the finish machined part in dry hydrogen or high vacuum to 1700 °F(927°C) (heating rate is not critical) and hold at 1700°F

927°C) for three to four hours. Cool at 20°F (11°C) maximum per hour to 1350°F (732°C), then col to 950°F (510°C) at 200°F

(111°C) per hour. Cool at any rate thereafter.

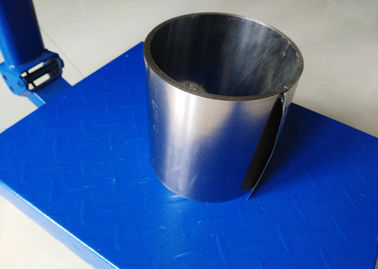

Form of supply

Cold rolled strip: thickness 0.05-2.0mm, width 20-300mm

Hot forged round bar: diameter 20-300mm

![]()

![]()

![]()

About XUNSHI

Suzhou Xunshi New Material Co. Ltd- referred as XUNSHI hereafter, is a professional manufacturer of high-performance alloy products. XUNSHI is engaged in supplying high quality and cost-effective Superalloy, Anti-Corrosion Alloy, Precision Alloy, Special Stainless Steel and Magnetostrictive Material to customers worldwide.

Why XUNSHI

· Highly experienced in alloy industry

· Top experts of industry in China

· Advanced technology and process from top famous institutes in China

· Advanced devices through whole production and inspection process

· Strict quality control system

· Company motto: best service, most value

· Smart sales policy

Service Items of XUNSHI

· Non-standard product research and pre-production

· Fabrication of products

· Cutting, splitting for sheets and plates in stock

· Heat treatment (Solution treatment, aging harden treatment, anneal, spring temper, quench etc.)

· Surface finish (peeling, gridding, polishing)

· Logistics service

· Customized packing service (also for exporting)

· Import and export (XUNSHI is certificated)

· Document translation

· Hard-to-find material sourcing

Customers of XUNSHI

Customers of XUNSHI are all over China (Taiwan and Hong Kong included). And we are exporting to USA, Canada, Italy, UK, Poland, Greece, Russia, Turkey, Iran, Israel, South Africa, South Korea, North Korea, India, Argentina, and Brazil and so on. Customers from 30+ countries trust us.

Where is XUNSHI

A- XUNSHI is in Huaqiao, Kunshan, 215332 China, which is very closed to Shanghai.

B- Xunshi is around 80KM from Shanghai Pudong International Airport (PVG).

C- 20KM from Shanghai Hongqiao Airport

D- 20KM from Shanghai Hongqiao Railway Station

E- You can contact XUNSHI sales for a pickup service.