-

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy!

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy! -

Carolina FasioOn-time delivery. And support is good and fast.

Carolina FasioOn-time delivery. And support is good and fast.

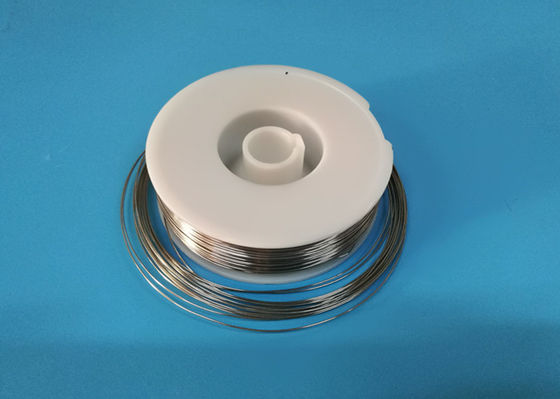

Capillcary Low Expansion Alloys -100°C To +200°C W.Nr 1.3912 For Laser Components

| Equal Grades | UNS K93600, Invar 36, Nilo 36, Ni36, Alloy 36 | Forms Of Supply | Wire, Strip, Bar, Tube, Capillcary, Forging |

|---|---|---|---|

| Density | 811g/cm3 | Melting Point | 1430°C |

| Coefficient Of Expansion | 1.5 µm/m °C (20 – 100°C), 2.6 µm/m °C (20 – 200°C) | Product Name | Low Expansion Alloys |

| Highlight | thermal expansion nickel,corrosion resistant alloys |

||

W.Nr 1.3912 Low Coefficient of Thermal Expansion Ranges from -100°C to +200°C.

W.Nr 1.3912 is an iron-nickel alloy with a very low coefficient of thermal expansion in the temperature range -100°C to +200°C.

Typical applications are moulds for composite components, piezoelectric injectors, echoboxes and filters for mobile telephone relay stations.

Chemical composition

| Element | Ni | Fe | C | Mn | P | S | Si | Cr | Mo | Co |

| Weight(%) | 35.0~38.0 | Rem | 0.10 max | 0.60 max | 0.025 max | 0.025 max | 0.35 max | 0.50 max | 0.50 max | 1.0 max |

Features

- Low expansion alloy. Maintains near constant dimensions over the range of normal atmospheric temperatures.

- Low coefficient of expansion from cryogenic temperatures to about +500°C (+930°F). Retains strength and toughness at cryogenic temperatures.

Applications

- Standards of length (measurement reference)

- Thermostat rods

- Laser components

- Tanks and piping for the storage and transportation of liquefied gasses

![]()