-

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy!

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy! -

Carolina FasioOn-time delivery. And support is good and fast.

Carolina FasioOn-time delivery. And support is good and fast.

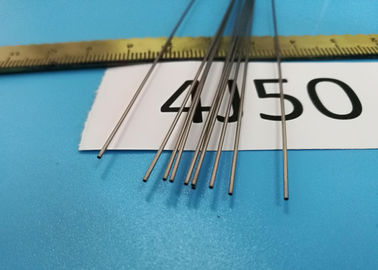

Aluminum 0.10 Max Alloy 52 , Soft Glasses Ceramics Sealing High Strength Alloy

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Equal Grade | UNS N14052 | Density | 8.3g/cm3 |

|---|---|---|---|

| Forms Of Supply | Rod, Wire, Forging, Round Bar, Strip | Spec | ASTM F30, 2.4478, FeNi52 |

| Product Name | Controlled Expansion Alloys | Certification | ISO9001 |

| Highlight | iron nickel alloy,thermal expansion nickel |

||

Alloy 52 Controlled Expansion Alloy for Soft Glasses and Ceramics Sealing

Alloy 52 was developed for glass-to-metal seals for some of the soft glasses and ceramics. The alloy’s rate of thermal expansion is virtually constant to a temperature of about 1050°F (565°C).

Key features

- Near zero coefficient of linear thermal expansion

- High strength and toughness at cryogenic temperatures

Applications

- Magnetic reed switches

- Glass to metal seals that need controlled linear expansion

Typical chemical composition

- Carbon: 0.05 max

- Silicon: 0.30 max

- Manganese: 0.60 max

- Nickel: 50.5 nom

- Chromium: 0.25 max

- Iron: Balance

- Phosphorus: 0.025 max

- Sulfur: 0.025 max

- Aluminum: 0.10 max

Physical Properties

Density: 0.30 lb/in³, 8.30 g/cm³

Electrical Resistivity: ohm-cir-mil/ft, microhm-cm:

At 68°F (20°C): 258(43)

Thermal Conductivity: BTU-in/hr-ft²-°F (W/m•K):

68-212°F (20-100°C): 97(140)

Mean Coefficient of Thermal Expansion: µin/in-°F (µm/m-°C):

77-842°F (25-450°C): 5.4 (9.8)

Melting Point: 2600°F (1430°C)

Mechanical Properties at Room Temperature

Properties: Annealed Typical

Ultimate Tensile Strength: 78 KSI nom (536 MPa nom)

Yield Strength: 35 KSI nom (240 MPa nom) Elongation: 30% nom

Hardness: Rb 73 nom

Properties Tempered

Please feel free to contact A-ONE ALLOY for your customized requirements.