-

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy!

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy! -

Carolina FasioOn-time delivery. And support is good and fast.

Carolina FasioOn-time delivery. And support is good and fast.

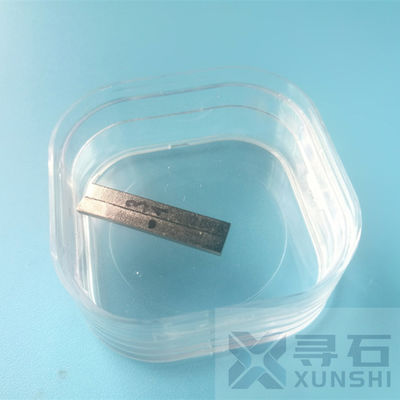

Ni50-Mn28-Ga22 Magnetostrictive Material Magnetic Shape Memory Alloy MSMA

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Ni50-Mn28-Ga22 | Magnetostriction | Up To 6% |

|---|---|---|---|

| Product Forms | Plate, Bar, Rod | Application | Magnetostrictive Transducer Element |

| Brand | XUNSHI | Certificate | ISO |

| Highlight | Plate Magnetic Shape Memory Alloy,Ni50-Mn28-Ga22 Magnetostrictive Material,Magnetostrictive Material Magnetic Shape Memory Alloy |

||

Magnetostrcitive Material Magnetic Shape Memory Alloy MSMA

The Magnetic Shape Memory (MSM) eàect in a Ni-Mn-Ga alloy was discovered in 1996 at MIT by Dr. Kari Ullakko and co-workers

The first MSM alloy showed a strain of 0.2%. Since then, huge improvements have been achieved in the production process

of MSM alloys as well as in the post-production treatments and training.

The Magnetic Shape Memory (MSMA) is a new type of functional material that the heat-induced Martenitic phase transition occurs only under the temperature field, and also is stress-induced and magnetic-induced ones. The main component of the Magnetic Shape Memory Alloy (MSMA) is Ni-Mn-Ga, and the linear deformation rate reaches 10% at room temperature.

MSM alloys are ferromagnetic materials that produce motion and force under moderate magnetic fields (typically higher than 0.2 T). They are single crystalline alloys of Nickel, Manganese and Gallium and are able to produce 6% strain under more than 2 MPa external load (see Fig. 3). Frequencies up to lower kilohertz range can be achieved.

Characteristics of the Magnetic Shape Memory Alloy for commercial use

- Typical strain up to 6%

- Blocking stress up to 3.5 MPa

- Magnetic Õeld for maximum strain of about 500 kA/m

- Full strain up to about 2 MPa load

- Work output per unit volume of about 150 kJ/m³

- Energetic eÞciency up to 90%

- Reaction times of about 1 ms (in MSM actuators)

- Hysteresis between stress or magnetic Õeld and strain (material damping)

- Internal friction

- Magnetic and thermal activation are both possible

- Operating temperatures: -40 °C to 60 °C

- Change in magnetic permeability and electric resistivity during deformation

As the professional magnetostrictive materials suppliers in China, we can provide high performance NiMnGa single crystal materials with specifications of multiple sizes to domestic and foreign customers, the minimum size is 0.5mm,the maximum size is 30mm.

General dimensions

- 1x2.5x20mm

- 2x3x15mm

- 3x5x20mm

The minimum order quantity is 5pcs.

![]()

![]()

![]()

About XUNSHI

Suzhou Xunshi New Material Co. Ltd- referred as XUNSHI hereafter, is a professional manufacturer of high-performance alloy products. XUNSHI is engaged in supplying high quality and cost-effective Superalloy, Anti-Corrosion Alloy, Precision Alloy, Special Stainless Steel and Magnetostrictive Material to customers worldwide.

Why XUNSHI

· Highly experienced in alloy industry

· Top experts of industry in China

· Advanced technology and process from top famous institutes in China

· Advanced devices through whole production and inspection process

· Strict quality control system

· Company motto: best service, most value

· Smart sales policy

Service Items of XUNSHI

· Non-standard product research and pre-production

· Fabrication of products

· Cutting, splitting for sheets and plates in stock

· Heat treatment (Solution treatment, aging harden treatment, anneal, spring temper, quench etc.)

· Surface finish (peeling, gridding, polishing)

· Logistics service

· Customized packing service (also for exporting)

· Import and export (XUNSHI is certificated)

· Document translation

· Hard-to-find material sourcing

Customers of XUNSHI

Customers of XUNSHI are all over China (Taiwan and Hong Kong included). And we are exporting to USA, Canada, Italy, UK, Poland, Greece, Russia, Turkey, Iran, Israel, South Africa, South Korea, North Korea, India, Argentina, and Brazil and so on. Customers from 30+ countries trust us.

Where is XUNSHI

A- XUNSHI is in Huaqiao, Kunshan, 215332 China, which is very closed to Shanghai.

B- Xunshi is around 80KM from Shanghai Pudong International Airport (PVG).

C- 20KM from Shanghai Hongqiao Airport

D- 20KM from Shanghai Hongqiao Railway Station

E- You can contact XUNSHI sales for a pickup service.