-

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy!

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy! -

Carolina FasioOn-time delivery. And support is good and fast.

Carolina FasioOn-time delivery. And support is good and fast.

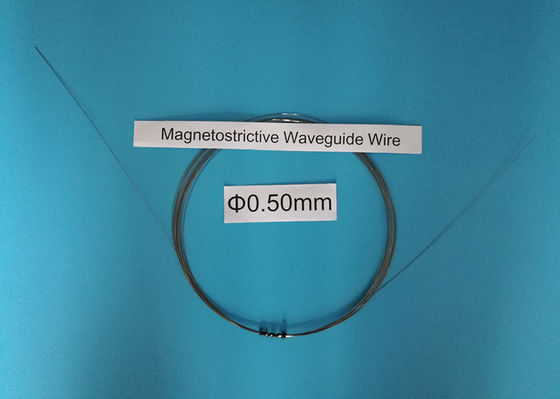

FeNi Alloy Magnetostrictive Waveguide Wire for Level Probe Diplacement Sensor

| Composition | FeNi Alloy | Size Available | 0.40-1.20mm |

|---|---|---|---|

| Stock Size | 0.50mm, 0.75mm, 0.80mm,1.0mm | Delivery Status | In Coil, Straight Wire |

| Product Name | Magnetostrictive Wire | Model | BDS-050 |

| Highlight | rare earth metals,rare earth materials,FeNi Alloy Waveguide Wire |

||

Magnetostrictive Waveguide Wire for Level Probe Diameter 0.50mm China Supplier

Xunshi is one of the most important magnetostrictive waveguide wire supplier in China. Xunshi has rich experience of supplying Magnetostrictive waveguide wire to customers from worldwide. Our wire is widely used in Magnetostrictive level gauge/sensor/probe. We keep stock of magnetostrictive alloy wire of diameter 0.50mm/0.75mm/0.80mm.

Magnetostriction is a property of ferromagnetic materials such as iron, nickel, and cobalt. When placed in a magnetic field, these materials change size and/or shape.

An important characteristic of a wire made of a magnetostrictive material is the Wiedemann effect. When an axial magnetic field is applied to a magnetostrictive wire, and a current is passed through the wire, a twisting occurs at the location of the axial magnetic field. The twisting is caused by interaction of the axial magnetic field, usually from a permanent magnet, with the magnetic field along the magnetostrictive wire, which is present due to the current in the wire.

The current is applied as a short-duration pulse, -1 or 2 µs; the minimum current density is along the center of the wire and the maximum at the wire surface. This is due to the skin effect.

The magnetic field intensity is also greatest at the wire surface. This aids in developing the waveguide twist. Since the current is applied as a pulse, the mechanical twisting travels in the wire as an ultrasonic wave. The magnetostrictive wire is therefore called the waveguide.

During the communication with customers XUNSHI learnt that straight wire is more convenient for the assemble and the signal is better as well. After years' experiment, XUNSHI sucessfully produced straight magnetostrictive waveguide wire. Several customers tested the sample and the result is really good.

| Diameter(mm) | Stock amont(meters) | Note |

| 0.50 | 100,000 | Straight wire in stock |

| 0.75 | 20,000 | Straight wire available on request |

| 0.80 | 12,500 | Straight wire available on request |

Packing:

The wire is packed in coil after being straightened for easy transport. When you release the coil, the wire becomes straight.

![]()

![]()