-

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy!

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy! -

Carolina FasioOn-time delivery. And support is good and fast.

Carolina FasioOn-time delivery. And support is good and fast.

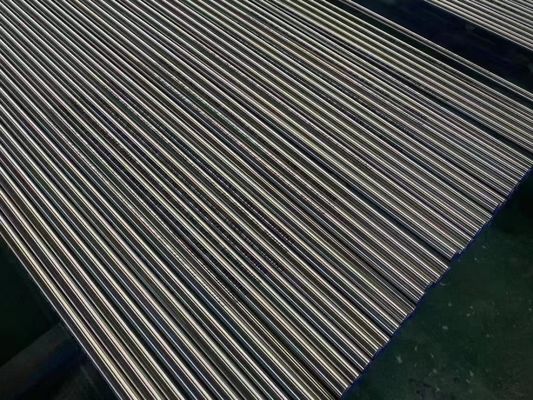

Hastelloy C276 Alloy UNS N10276 for Chemical Processing Components China Origin Fast Delivery

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Equal Grade | UNS N10276, Hastelloy C276, | Forms Of Supply | Forging, Bar, Wire, Tube, Pipe, Strip |

|---|---|---|---|

| Stock Items | Forging Round Bar | Fabrication Service | Yes |

| Heat Treatment Service | Yes | Product Name | Hastelloy Alloy |

| Highlight | Chemical Processing Components Hastelloy Alloy,Hastelloy C276 Alloy,UNS N10276 Hastelloy Alloy |

||

Hastelloy C276 Alloy UNS N10276 For Chemical Processing Components

Hastelloy C276 is one of the most well known corrosion resistant alloys in China. The name HASTELLOY is almost a symbol of corrosion resistant alloy. Hastelloy C276 is our featured product that the price is very competitve while the quality is among top suppliers in China.

C276 was developed in 1965,after 1970 using off-furnace refining (AOD,VOD) production to obtain ultra-low carbon and high purity. In order to reduce the disadvantages of consolidation heat treatment after welding or thermoforming, except for reducing carbon content, also the silicon content in the alloy reducing to 0.08%. Reducing the carbon content can reduce the amount of the carbon out quantity in the alloys, reducing the silicon content could reduce the amount of precipitation between metals in alloys, so that can achieve the purpose of increasing intercorrosion resistance of alloy. At the same time, the plasticity, toughness and processing properties of the alloy were improved.

Chemical composition(wt, %)

Advantages

- Excellent corrosion resistance in reducing environments

- Exceptional resistance to strong solutions of oxidizing salts, such as ferric and cupric chlorides

- High nickel and molybdenum contents providing good corrosion resistance in reducing environments

- Low carbon content which minimizes grain-boundary carbide precipitation during welding to maintain resistance to corrosion in heat-affected zones of welded joints

- Resistance to localized corrosion such as pitting and stress-corrosion cracking

- One of few materials to withstand the corrosive effects of wet chlorine gas, hypochlorite and chlorine dioxide

Applications

- Pollution control stack liners, ducts, dampers, scrubbers, stack-gas reheaters, fans and fan housings

- Flue gas desulfurization systems

- Chemical processing components like heat exchangers, reaction vessels, evaporators, and transfer piping

- Sour gas wells

- Pulp and paper production

- Waste treatment

- Pharmaceutical and food processing equipment

Available forms

Bar,Wire,Tube.Pipe,Plate.Strip,Forging

Equal grades

- NS3304

- NS334

- 00Cr16Ni60Mo16W4

- UNS N10276

- W.Nr.2.4819

- NC17D

- Alloy C276

Specs

| Form | Standard |

|---|---|

| Identification | UNS N10276, DIN 17744, DIN 17750 – 17754, W. Nr. 2.4819 |

| Bar | ASTM B574, ASTM B564, ASME SB574, ASME SB564 |

| Sheet, Plate, or Strip | ASTM B575, ASTM B906, ASME SB575, ASME SB906 |

| Pipe - Seamless | ASTM B622, ASME SB622 |

| Pipe - Welded | ASTM B619, ASME SB619 |

| Tube - Seamless | ASTM B622, ASTM B626, ASME SB622, ASME SB626 |

| Tube - Welded | ASTM B626, ASTM B751, ASME SB626, ASME SB751 |

| Fitting | ASTM B366, ASTM B462, ASME SB366, ASME SB462 |

| Forging | ASTM B564, ASTM B574, ASME SB564, ASME SB574 |

| Weld Wire | UNS N10276/ W. Nr. 2.4886/ AWS A5.14 ERNiCrMo-4/ ASME IX F-No. 43 |

| Weld Electrode | UNS W80276/ W. Nr. 2.4887/ AWS A5.11 ENiCrMo-4/ ASME IX F-No. 43 |

Please feel free to contact us for your requirements of Hastelloy C276.

![]()

![]()

![]()

![]()

![]()

About XUNSHI

Suzhou Xunshi New Material Co. Ltd- referred as XUNSHI hereafter, is a professional manufacturer of high-performance alloy products. XUNSHI is engaged in supplying high quality and cost-effective Superalloy, Anti-Corrosion Alloy, Precision Alloy, Special Stainless Steel and Magnetostrictive Material to customers worldwide.

Why XUNSHI

· Highly experienced in alloy industry

· Top experts of industry in China

· Advanced technology and process from top famous institutes in China

· Advanced devices through whole production and inspection process

· Strict quality control system

· Company motto: best service, most value

· Smart sales policy

Service Items of XUNSHI

· Non-standard product research and pre-production

· Fabrication of products

· Cutting, splitting for sheets and plates in stock

· Heat treatment (Solution treatment, aging harden treatment, anneal, spring temper, quench etc.)

· Surface finish (peeling, gridding, polishing)

· Logistics service

· Customized packing service (also for exporting)

· Import and export (XUNSHI is certificated)

· Document translation

· Hard-to-find material sourcing

Customers of XUNSHI

Customers of XUNSHI are all over China (Taiwan and Hong Kong included). And we are exporting to USA, Canada, Italy, UK, Poland, Greece, Russia, Turkey, Iran, Israel, South Africa, South Korea, North Korea, India, Argentina, and Brazil and so on. Customers from 30+ countries trust us.

Where is XUNSHI

A- XUNSHI is in Huaqiao, Kunshan, 215332 China, which is very closed to Shanghai.

B- Xunshi is around 80KM from Shanghai Pudong International Airport (PVG).

C- 20KM from Shanghai Hongqiao Airport

D- 20KM from Shanghai Hongqiao Railway Station

E- You can contact XUNSHI sales for a pickup service.