-

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy!

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy! -

Carolina FasioOn-time delivery. And support is good and fast.

Carolina FasioOn-time delivery. And support is good and fast.

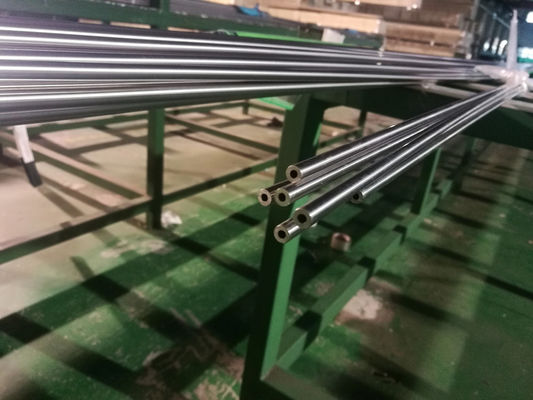

Aermet 100 High Strength Martensitic Stainless Steel Rod Dia 20-400mm

| Equal Grade | Aremet 100 | Diameter Range | 20-400mm |

|---|---|---|---|

| Product Name | Aremet100 Martensitic Steel | Certification | ISO 9001:2015 |

| Model | A-100 | Brand | XUNSHI |

| Highlight | Aermet 100 Stainless Steel Rod,Martensitic Stainless Steel Rod,Special Stainless Steel Aermet 100 |

||

Aermet100 High Strength Martensitic Stainless Steel Rod Dia 20-400mm

AerMet 100 high-strength steel can be used in operating condition up to 427 °C (800 °F). A-100 Aermet100 is an type of martensitic steel alloy, It has a very hard form of steel crystalline structurewas and developed in response to a need for a stroultra-high strengthnger and tougher material with superior fracture toughness and ductility. The minimum tensile strength of the alloy is 280 ksi (1930 MPa).

Due to the alloy is not a corrosion-resistant alloy, the sealing must be performed if used in a wet environment. Excellent hardness, tensile strength, and ductility make the alloy a candidate for various applications, including landing gear, armor, fasteners, actuators, ordnance, jet aircraft, engine shafts, drive axles, and structural tubes.

Parameters

Density: 7.9g/cm3(0.285lb/in3)

Elastic modulus: 28.2 * 103KSI

Resresistivity: 259.0 ohm-cir-mil / ft (70.0 ° F)

Advantages

- High hardness and strength

- Excellent mechanical performance

- Safety belts and strength

- Excellent ductility and toughness

- High fracture toughness

- Excellent fatigue and stress corrosion cracking resistance

- High fatigue strength

Normalizing

AerMet 100 alloy can be normalized by heating to 1650° F (899° C) holding for one hour and air cooling to room temperature. Optimum softening for machining is obtained by following the 1650° F (899° C) normalize with a 16 hour 1250° F (677° C) overage anneal.

Annealing

Cold Treatment

Cooling to room temperature, to obtain the full toughness capability AerMet 100 alloy should be cooled to -100° F (-73° C) and held for 1 hour. The parts can then be air warmed.

Typical mechanical properties

Heat treatment - 1625° F (885° C) one hour, cooling, -100° F (-73° C) one hour, 900° F (482° C) for 5 hours.

Hardness: HRC53-54

UTS(KSI):285

Elongation:14%

Breaking extensibility :65%

Specifications

AMS 6532,UNSK92580

Available forms

Forgings, rods, square rods, plate, strip, wire, welding wire, etc., with a diameter range of 20-400mm

![]()

![]()

![]()

About XUNSHI

Suzhou Xunshi New Material Co. Ltd- referred as XUNSHI hereafter, is a professional manufacturer of high-performance alloy products. XUNSHI is engaged in supplying high quality and cost-effective Superalloy, Anti-Corrosion Alloy, Precision Alloy, Special Stainless Steel and Magnetostrictive Material to customers worldwide.

Why XUNSHI

· Highly experienced in alloy industry

· Top experts of industry in China

· Advanced technology and process from top famous institutes in China

· Advanced devices through whole production and inspection process

· Strict quality control system

· Company motto: best service, most value

· Smart sales policy

Service Items of XUNSHI

· Non-standard product research and pre-production

· Fabrication of products

· Cutting, splitting for sheets and plates in stock

· Heat treatment (Solution treatment, aging harden treatment, anneal, spring temper, quench etc.)

· Surface finish (peeling, gridding, polishing)

· Logistics service

· Customized packing service (also for exporting)

· Import and export (XUNSHI is certificated)

· Document translation

· Hard-to-find material sourcing

Customers of XUNSHI

Customers of XUNSHI are all over China (Taiwan and Hong Kong included). And we are exporting to USA, Canada, Italy, UK, Poland, Greece, Russia, Turkey, Iran, Israel, South Africa, South Korea, North Korea, India, Argentina, and Brazil and so on. Customers from 30+ countries trust us.

Where is XUNSHI

A- XUNSHI is in Huaqiao, Kunshan, 215332 China, which is very closed to Shanghai.

B- Xunshi is around 80KM from Shanghai Pudong International Airport (PVG).

C- 20KM from Shanghai Hongqiao Airport

D- 20KM from Shanghai Hongqiao Railway Station

E- You can contact XUNSHI sales for a pickup service.