-

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy!

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy! -

Carolina FasioOn-time delivery. And support is good and fast.

Carolina FasioOn-time delivery. And support is good and fast.

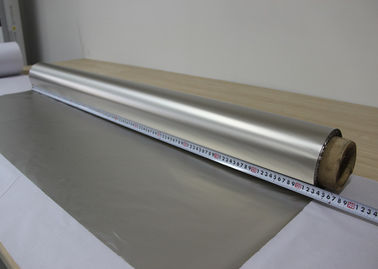

Controlled Expansion Kovar Alloy , Hard Glass Sealing Iron nickel cobalt Alloy

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Equal Grade | 4J29, ASTM F-15, NILO K, Pernifer 2918, Rodar, Dilvar P1 | Alloy Type | FeNiCo |

|---|---|---|---|

| Forms Of Supply | Bar, Tube, Sheet, Plate, Strip, Wire, Capillary, Forging, Finewire | Spec | ASTM F-15 |

| Product Name | Controlled Expansion Alloys | Model | Kovar |

| Highlight | iron nickel alloy,thermal expansion nickel |

||

Kovar Controlled Expansion Alloy Iron-nickel-cobalt Alloy for Hard Glass Sealing

Kovar is one of the most popular of the controlled expansion alloys for hermetic sealing applications. And it is one of A-ONE ALLOY's featured products. We stocks Kovar sheet, Kovar plate, Kovar rod, Kovar strip, Kovar wire, Kovar round bar as well as ingot. We make fast delivery to meet customer requirements.

And we also delivery Kovar in form of pipe, tube, capillary and part per customer spec&drawing.

Kovar was invented to meet the requirement for a reliable glass-to-metal seal. It is required in electronic devices such as light bulbs, vacuum tubes, cathode ray tubes, and in vacuum systems in chemistry and other scientific research. Most metals could not seal to glass because their coefficient of thermal expansion is not the same as glass, so as the joint cools after fabrication the stresses due to the differential expansion rates of the glass and metal cause the joint to crack.

Kovar’s non-linear thermal expansion curve can often be made to match a glass, thus allowing the joint to tolerate a wide temperature range. Chemically, it bonds to glass via the intermediate oxide layer of nickel oxide and cobalt oxide; the proportion of iron oxide is low due to its reduction with cobalt. The bond strength is highly dependent on the oxide layer thickness and character the presence of cobalt makes the oxide layer easier to melt and dissolve in the molten glass. A grey, grey-blue or grey-brown colour indicates a good seal. A metallic colour indicates lack of oxide, while black colour indicates overly oxidized metal, in both cases leading to a weak joint.

Chemical composition

29% Nickel, 17% Cobalt

Density: 8.24g/cm3

Coefficient of Thermal Expansion (Nominal):

30 oC - 400 oC 4.90(µm/m- oC)

25 oC - 300 oC 5.13(µm/m- oC)

30 oC - 450 oC 5.30(µm/m- oC)

25 oC - 100 oC 5.86(µm/m- oC)

25 oC - 500 oC 6.15(µm/m- oC)

25 oC - 900 oC 11.26(µm/m- oC)

![]()