-

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy!

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy! -

Carolina FasioOn-time delivery. And support is good and fast.

Carolina FasioOn-time delivery. And support is good and fast.

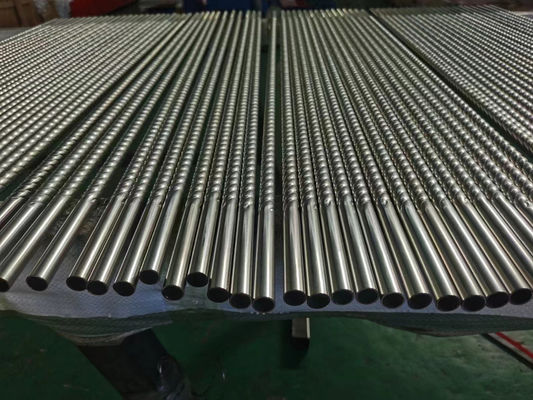

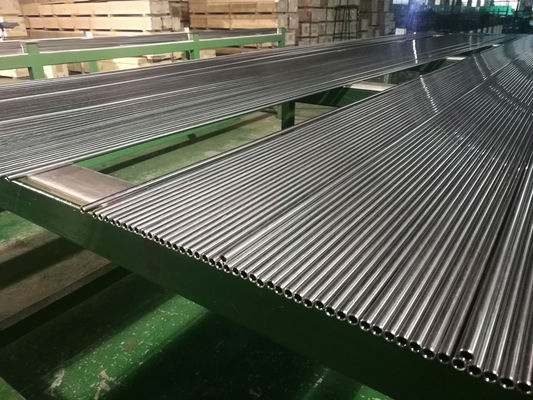

Hastelloy C4 Alloy Forged Round Bar with Good Ductility and Corrosion Resistance

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Equal Grades | Hastelloy C-4, NS335, NS3305, 2.4610 | Form Of Supply | Round Bar, Forging, Seamless Tube, Plate, Strip, Wire, Fitting |

|---|---|---|---|

| Spec | ASTM B574, ASTM B619 | Product Name | Hastelloy Alloy |

| Certification | ISO9001:2015 | Character | High-temperature Stability |

| Highlight | machining nickel alloys,nickel chromium iron alloy |

||

Introduction

Hastelloy C4 is a nickel-chromium-molybdenum alloy which has improved thermal stability. In this alloy, the tungsten was totally omitted and the iron content was reduced to approximately 1%. The alloy also contains approximately 0.3% Ti.

Density:8.64g/cm3

Character

Outstanding high-temperature stability; exhibits good ductility and corrosion resistance after long-time aging at 650 to 1040 °C (1200–1900 °F). Resists formation of grain-boundary precipitates in weld heat-affected zones, and is suitable for most chemical process applications in the as-welded condition. Has excellent resistance to stress-corrosion cracking and to oxidizing atmospheres up to 1040 °C (1900 °F).

Hastelloy C4 has exceptional resistance to a variety of chemical process environments, including hot contaminated mineral acids, solvents, chlorine, and chlorine-contaminated media (organic and inorganic, dry chlorine, formic and acetic acids, acetic anhydride, seawater, and brine). The general corrosion resistance of Alloy C276 and Alloy C4 was essentially the same in many corrosive environments, except that in strongly reducing media like hydrochloric acid, Alloy C276 was better; but in highly oxidizing media, the opposite was true, that is, Alloy C4 was better. Alloy C4 offers good corrosion resistance to a wide variety of media including organic acids and acid chloride solutions. This alloy has found greater acceptance in European countries in contrast to Alloy C276, which is more widely used and accepted in the United States.

Application

It has been widely used in the field of chemical engineering and high temperature environment. Typical application areas:

- Flue gas desulfurization system

- Acid pickling and acid recycling plant

- Acetic acid and agricultural chemicals production

- Titanium dioxide production (chlorine method)

- Electrolytic plating

Chemical composition (%)

Cr=14.00~18.00, Mo=14.00~17.00, Fe≤3.00, C≤0.015, Si≤0.08, Co≤2.00, Mn≤1.00, P=≤0.04, S≤0.03, Ti≤0.07, Ni=Remainder

![]()