-

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy!

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy! -

Carolina FasioOn-time delivery. And support is good and fast.

Carolina FasioOn-time delivery. And support is good and fast.

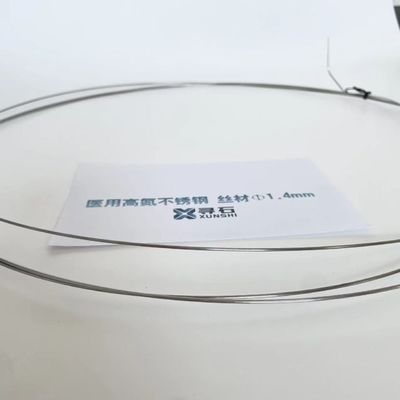

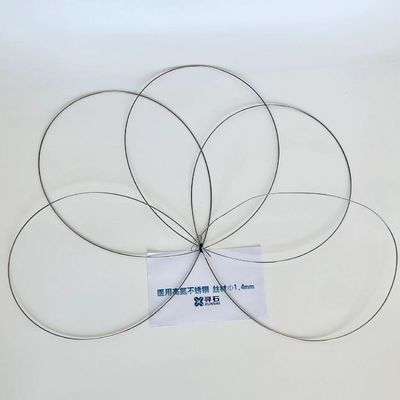

S31675 High Nitrogen Stainless Steel Wire For Surgical Implants ASTM F1586 ISO 5832-9 No Ni

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Smelting Process | Electroslag Remelting (ESR) | ISO Standard | ISO 5832-9 |

|---|---|---|---|

| ASTM Standard | ASTM F1586 | Scope Of Use | High End Medical Stainless Steel |

| Delivery Status | Annealed State | Producing Area | Jiangsu China |

| Tensile Strength Rm/MP | 35 | Prescribed Non Proportional Elongation Strength Rp0.2/MPa | 430 |

| Can It Be Processed | Yes | ||

| High Light | High Nitrogen Special Stainless Steel Wire,S31675 Stainless Steel Wire,Surgical Implants Stainless Steel Wire |

||

S31675 stainless steel for high nitrogen surgical implants

In recent years, the demand for high-end medical stainless steel has been increasing, and due to the high cost of imported medical stainless steel, long delivery cycles, and high communication costs, the call for the localization of high-end medical stainless steel has also been increasing. The domestically produced S31675 high nitrogen stainless steel was born in this context.

S31675 (ASTMF1586) is a nitrogen reinforced stainless steel for surgical implants, mainly used for hip and knee joints and fracture fixation devices. Its special use requires the material to be very "pure", which means that the content of non-metallic inclusions such as sulfides, alumina, silicates, and spherical oxides is low. This grade of stainless steel is usually produced using the electroslag remelting (ESR) smelting process. ESR is a super refining process that enables stainless steel to have excellent micro cleaning levels that meet regulatory requirements. It can also meet other special requirements of these ASTM standards for implant materials, such as having fine grain structure. The domestically produced S31675 adopts the same production process as Europe and America, and its quality is not inferior to imported products. And it has significant advantages in terms of price, delivery cycle, and minimum order quantity.

Relevant standards

ASTMF1586

ISO5832-9

YY0605.9-2007- Metallic Materials for Surgical Implants - Part 9: Forged High Nitrogen Stainless Steel

EN10088-309/05X4CrNiMnMo21-9-4

2.4772

M30NW

chemical composition

| element | C | Mn | P | S | Si | Cr | Ni | Mo | N | Nb | Cu | Fe |

|

proportion (Mass%) |

0.08 max | 2.00-4.25 | 0.025 max | 0.01 max | 0.75 max | 19.50-22.00 | 9.00-11.00 | 2.0-3.0 | 0.25-0.50 | 0.25-0.80 | 0.25 max | Bal |

mechanical property

| Delivery status | Diameter or thickness/mm | Tensile strength Rm/MPa | Prescribed non proportional elongation strength Rp0.2/MPa |

Elongation after fracture (A/%) |

| Annealed state | Full size | 740 | 430 | 35 |

| Semi hard state | 1.59-19.1 | 1000 | 700 | 20 |

| Hard state | 1.59-19.1 | 1100 | 1000 | 10 |

Grain size

Determine the grain size of austenite according to the prescribed method, and the result should not be coarser than level 5.

No foreign phase

According to the specified method, there should be no presence in the microstructure of the steel δ Ferrite χ Xianghe σ Phase.

Inclusion content

According to the prescribed method, the content of non-metallic inclusions in steel measured on a section of billet or bar with a thickness not exceeding 150mm should not exceed the provisions in the following table

Note: Generally, electroslag remelting steel is used to meet purity requirements and gain other advantages.

| Inclusion type | Reference level for inclusion content | |

| Fine series | Coarse series | |

|

sulfide alumina silicate Spherical oxide |

1.5 2 2 2.5 |

1.5 1.5 1.5 1.5 |

characteristic

S31675 stainless steel has good corrosion resistance and good mechanical properties.

Strict raw material selection and smelting process ensure the extremely high quality required for the production of stainless steel for surgical implants.

Due to its composition and absence of ferrite, the steel is completely non magnetic and exhibits excellent resistance to pitting and crevice corrosion in physiological media (Cr%+3.3Mo%+15N%>32).

The stabilizing effect of niobium can generate excellent intergranular corrosion resistance.

The combination of smelting and processing processes ensures that the product can obtain uniform, fine-grained materials with very low inclusion levels. This ensures that the product has excellent fatigue resistance, which is ideal for producing parts that withstand high stress.

Product form

Wire, bar, plate, strip, seamless tube, capillary tube

![]()