-

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy!

Daniel WereeHave been business relationship for 3 years, great partner for Nickel Cobalt Alloy! -

Carolina FasioOn-time delivery. And support is good and fast.

Carolina FasioOn-time delivery. And support is good and fast.

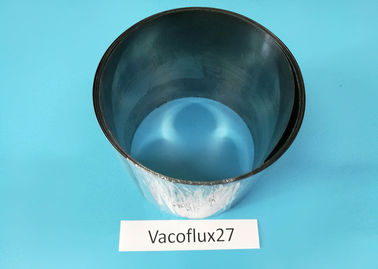

UNS K92650 Wrought Alloy Steel Magnetic , Cold Drawn Wire Magnetic Core Material

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Equal Grades | 1J27, FeCo27, HiperCo27, Vacoflux27 | Spec | ASTM A801-2014 |

|---|---|---|---|

| Type | FeCo Alloy | Forms | Round Bar, Cold Rolled Strip, Cold Drawn Wire |

| Product Name | Soft Magnetic Alloys | Package | Plawoode Crate |

| High Light | soft magnetic iron,soft iron material |

||

UNS K92650 Wrought Iron-Cobalt High Magnetic Saturation Alloy

K92650 is a rought iron-cobalt alloy used in magnetic components requiring high permeability at and above 15 kG (1.5 T) or high magnetic saturation.

ASTM A801 covers material supplied by a producer in the form and physical condition suitable for

fabrication into parts that will later be given final heat treatment to achieve the desired magnetic characteristics and, where required, mechanical properties. It covers material supplied in form of forging billets, hot-rolled products (that is, bar, plate, and strip), cold-finished bars, and cold-rolled strip. But it does not cover parts produced by casting or by powder metallurgical techniques.

Chemical Requirements(Weight Percent)

Carbon, max 0.025

Manganese, max 0.35

Silicon, max 0.35

Phosphorus, max 0.015

Sulfur, max 0.015

Chromium, max 0.75

Nickel, max 0.75

Cobalt 26.50 to 28.50

Vanadium max 0.35

Iron remainder

Characters

- High magnetic saturation

- Good mechanical toughness

- Good ductility

- High saturation induction

- High curie temperature: 925 °C

Applications

Motors, generators, pole pieces, relays and magnetic bearing.

Standards

ASTM A801 Standard Specification for Wrought Iron-Cobalt High Magnetic Saturation Alloys (UNS R30005 and K92650)

Heat treatment

K92650 is typically heat treated between 845 and 865°C for the best magnetic performance. It may also be heat treated at temperatures as high as 975°C.